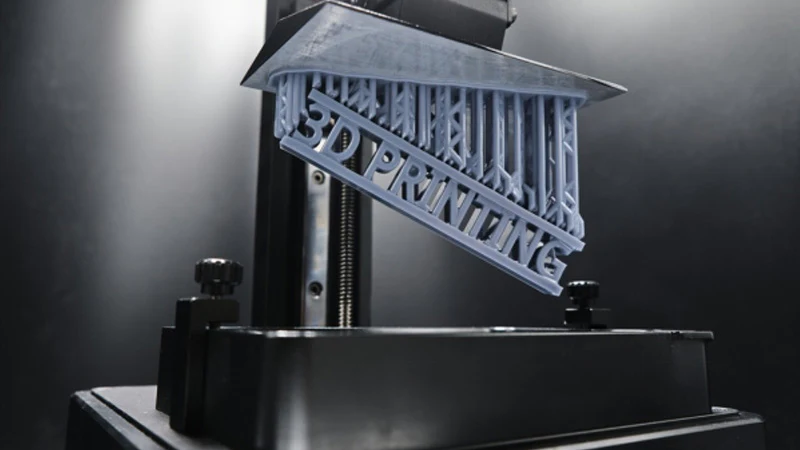

Printing quality is something subjective, everyone has his own degree of quality. So to face the problem, we’ve developed a method. At Dimville Factory, we have defined printing quality in 2 parts:

- #1 External appearance

- #2 Internal structure

For us, a good printing should respond to all of those points. If only one missing, we solve the problem and re-print until it’s perfect. We only do exception, for prototype, some of “default” could be ignore. Our “quality checklist” is quite important, but there are few points you should be aware to.

#1 External appearance:

- The printing should be exact copy of the 3D design. We take measures with caliper to make sure everything is ok, our tolerance is 0.05mm

- No missing layer or part of a layer, due to clogged extruder, that

- No highly visible seams. Seams are parts of a printing, you can’t avoid but we’ve found solutions to minimize the visibility. Most of the time, invisible.

- No “blob”, when the printer over-extrude, blobs could appear.

- No stringing, that appear during extruder traveling. Depending the material we use, that could be more or less a pain.

- No deformation, during printing, the material is heated then cool-down. A wrong bed adhesion will produce a part deformation.

- Fitting between parts, if a part is too loose or too tight but measures are ok, we check back the 3D file.

- Wrong flatness, the 1st layer should be perfectly flat.

- No elephant foot print, when the Z offset is badly set or slicer not tune, the 1st layer appear to be larger as it should. May also result a bad fitting.

#2 Internal structure:

- Minimal infill of 5%, that’s mean the infill will be 5% of the total part’s volume. Following the printing usage, we adjust the infill.

- No infill under extrusion, during printing, regular checks are made to avoid missing infill layers.

- No stringing inside, a badly set printer will produce tones of stringing inside the printing part. That means structural integrity is compromise.

- No infill pattern deformation, we always check the infill pattern, it should be perfectly continuous with no deformation

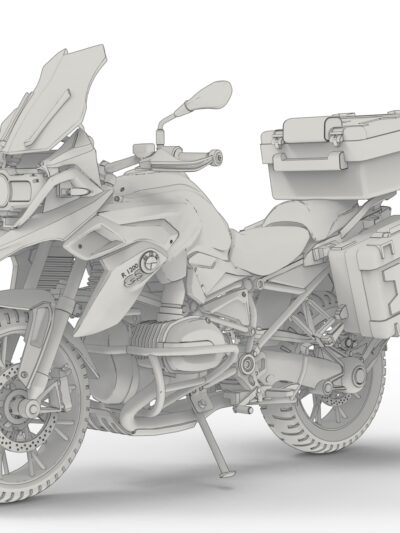

Few examples of bad printings, enjoy the horror show ????

[ngg src=”galleries” ids=”5″ display=”basic_thumbnail” thumbnail_crop=”0″]Dealing with quality is time and money consuming but worth it ! Our customers are waiting for the best quality, so we will always do everything to do better.

Now, about FAILS !

At Dimville Factory, we use FAIL word to officially say we’re fucked ???? Most of the time, it’s a wrong design that leads to a bad printing and we need to redo 90% of the design. Most of the time, it’s happen when have to produce parts for customers without visibility and they provide wrong datas or unit conversion. It’s very rare because we have a process to face that, but that could happen !

In that case, we de not care who’s in fault, if we ship a part good for us but not for the customer, we spot the problem(s) then produce again free of charge until the part is approuved.

Finally,

Whatever the problem, it’s always a chance to improuve the quality, the process, … The most important for us is to deliver the best quality in good time.

See also :