When you decide to create something, you have to respect a long way ! 3D printing is a very useful tool with many advantages, but if you fail on one point, you could wast many time and money.

We will expose you the reasons why it takes weeks to produce one model and cost us a lot of money.

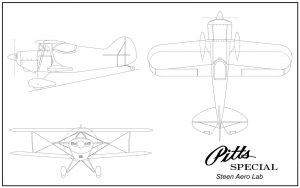

1# Documents:

Once we have a model to do, we have to search for documents about it ! More details you have, easier to design will be. We could easily find 3 views for old aircrafts but for prototype like the BR Racing bird, we have to trick with pictures.

Sometime we directly ask to the manufacturer, for example with Extra Aircraft, Jago Stemberger … That first part could take days !

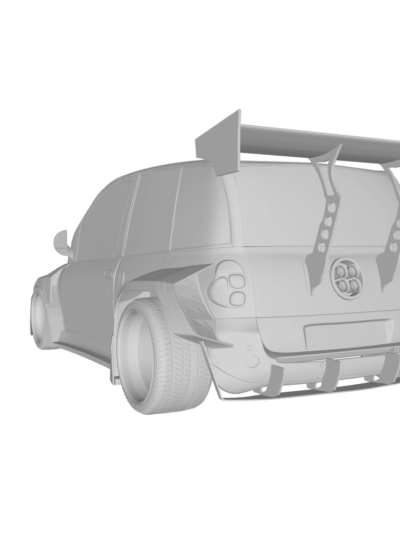

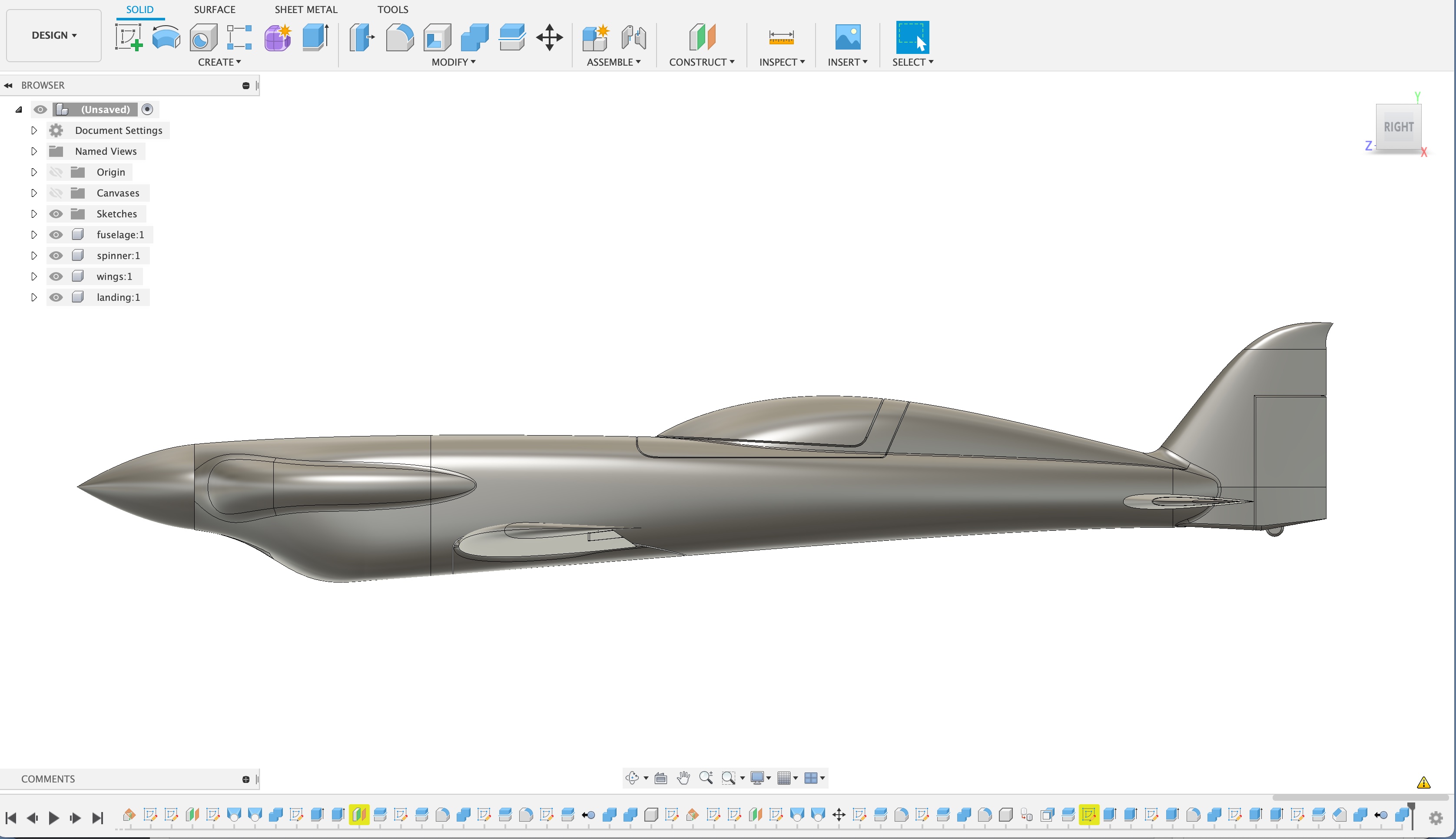

2# 3D Design:

Ok, now we have 2 or 3 views, let’s go for the core of the model ! Designing a model takes a couples of steps. We start with the general shape, fuselage, landings, fins, wing, prop. Then, we have to do the cuts for assembly respecting the production plays of the printer. An important point is to manage the “printability” of the model, sharp edges, small parts, angles, … Fully designing a model is around 2 weeks.

At this point we’re ready to print the first parts.

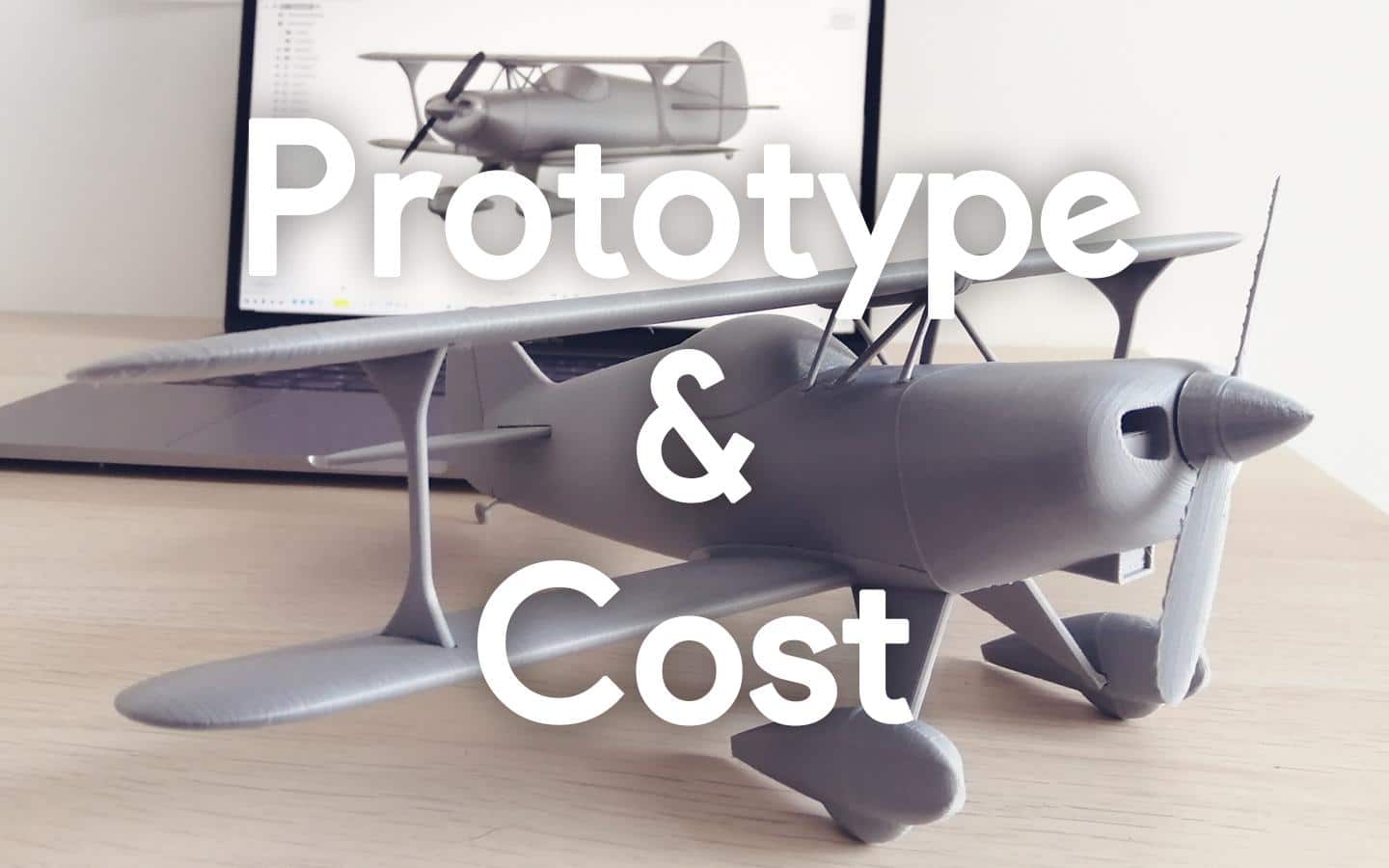

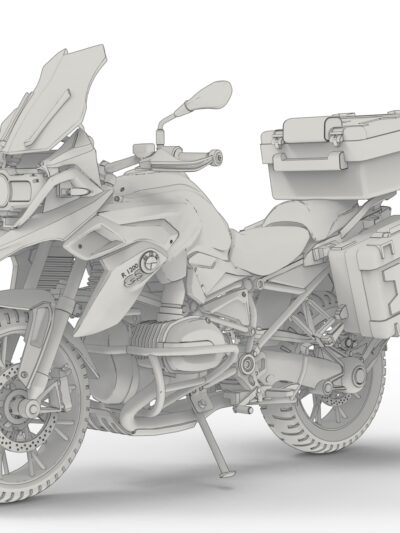

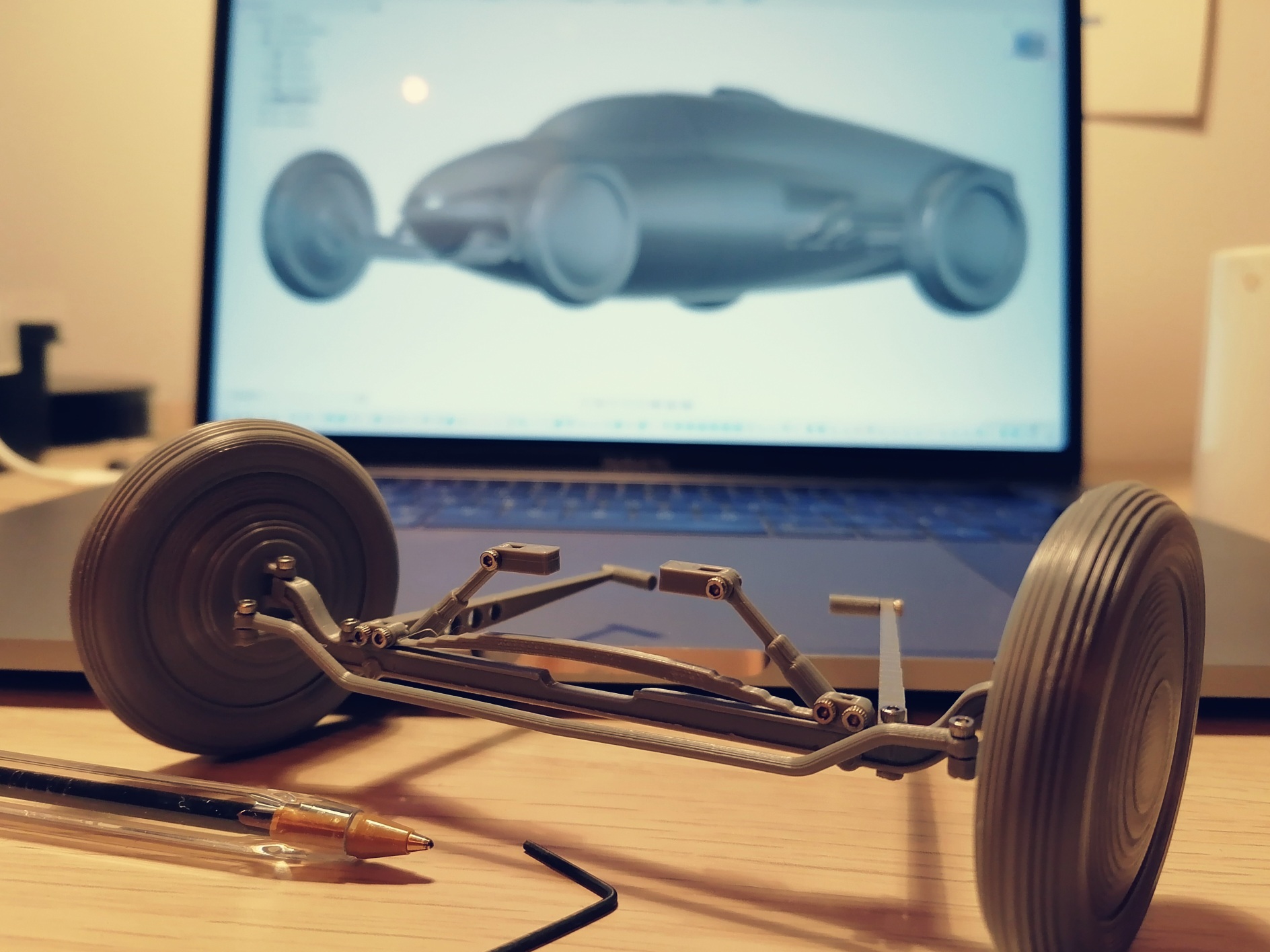

3# Prototype:

We always start to print the same parts to check the quality and assembly. We will keep the order secret, sorry ! To have a fully done prototype we have to print 2 or 3 models. Depending the difficulty, we could print 1 to 5 times the same part to redefine edges, shape, layer’s definition, …

That process takes 1 week to complete a pre-production prototype.

4# Pre-production:

At this point, we’ve already spent almost 4 weeks ! When everything is ok, files, settings, materials, (assuming the printer is 100% ok) we could print the pre-production model. Nothing big even if we could still have surprises. The goal is to check the printing time and quality. Make sure every time we will print that model we gonna have the same level of quality.

Usually takes 2 to 3 days to print a plane.

5# The cost:

Each step above has a cost ! We can’t tell you a price but our latest evaluations said between 500 and 800 euros.

Why that much ? While we spend time to search documents and designing, we can’t work for something else and we pay that time from our pocket ! Then, prototyping use filament, electricity, time, and at the end rising the cost. You also have to add the time spend for photos, web submissions, …

In conclusion,

With no surprise, prototyping is directly link to your final product’s quality. Care about feedbacks, good and bad, during the process is also very important. The real problem is to manage cost, time and benefit.

When a creator ask you couples of euros or dollars for his work, that’s not to buy the latest Porsche. We just expect to cover the cost of development and if magic happen, invest into new material to bring you more stuffs.

At Dimville Factory, for each model you could see, it’s over 1 month of free work, hundreds of euros spent. We’ve decided to keep quality first no matter the time it needs.

We also care a lot to customers feedbacks and spend time to update models following the reviews without extra fee.

So if you like our work, you could support us by sharing it and if you really love, purchase your kit ????

See also :